- Home

- EPS Light Weight Wall Panel Production Line

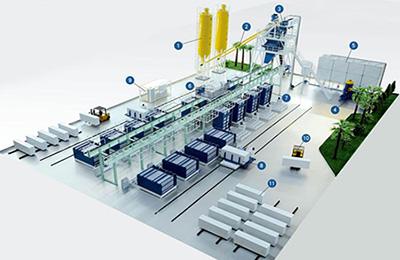

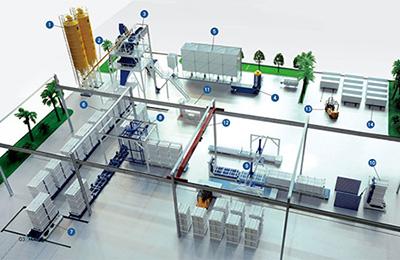

EPS Light Weight Wall Panel Production Line

With the rapid growth of the economy in the world, the construction industry has been developed vigorously with large demand of building materials. However, the traditional construction material can not meet the requirement of modernized material construction performance. The basic concept of the modern construction material is mainly reflected in the energy conservation, environment protection, comfort and sustainability. The materials have to be consistent with the construction progress in fast pace. Under such conditions, the EPS light-weight wall panel production line and advanced technologies are developed appropriately.

Our production line is applicable for making the EPS light-weight wall panel with different specifications. In general, the panel is about 3000mm long and 610mm wide, the thickness is from 50mm to 200mm.With the different mould, various wall panels can be produced. The annual output of this EPS light-weight wall panel production line could be from 100,000m² to 2,400,000m² to meet customers’ requirement.

- The EPS light-weight wall panel made by HONGYI production line is easily for mounting and assembling under construction. It is suitable to be used as the external cladding, interior separating wall and internal partition wall of various high buildings or multilayer building with nonbearing walls, and also for the roofing. The panel is especially applicable for the house that needs finishing in a short time, such as the building and villa with steel structure, etc.

- The EPS wall panel is about the 60kg/m² and it is about 1/6 of normal concrete brick, and 1/2 of AAC block. It reduces the occupation areas and increases the valid space of the building, saving the project cost.

- The panel made by our EPS light-weight wall panel production line is extremely waterproof and moisture resistant. In the humid weather conditions, there is not any coagulated water drop on it. Therefore, this panel has outstanding adaptability to the places with high humidity, such as kitchen, washroom, basement, etc.

- The EPS light-weight wall panel production line is good at processing the panels with excellent fire prevention performance. At 1000ºC, the panel is tested to keep fire resistance over 3.5 hours. The non-consumable performance complies with the A grade national standard. The wall panel adopts the thermal insulation material as the core part in the porous honeycomb structure. Consequently, it is featured with preeminent heat insulation function and energy saving performance.

- The EPS wall panel is with optimal sound insulation and absorbing effect. For example, the 90mm thick panel is able to absorb the sound about 43dB, which is higher than other concrete walls do.

- The EPS light-weight wall panel production line makes the panel that is make of eco-friendly composite materials that are free of harmful contents and A grace of radioactive substances, meeting the requirements of 5 National 169-2005 Standards. There is no limit on the application of the panels.

- In the construction, users can make the EPS wall panel for wiring, nailed and mounted with expanded bolt for hanging objects. The bearable weight of single point exceeds 50kg. As there is no dust on the surface of the panel, some materials can be adhered to the panel directly, such as tile, wall paint, etc.

- The composite wall panel fabricated by our EPS light-weight wall panel production line is characterized by high intensity and excellent impact resistance. It can be used as the partition wall with large span of multilayer buildings. Its integral seismic performance is several times higher than the ordinary masonry wall. With tightly connected structure, the composite panel is not easy to deform or become incompact.